HP’s 3D Printing and Digital Manufacturing Center in Barcelona/Courtesy: HP

Hewlett-Packard (HP) invented and developed the Multi Jet Fusion (MJF) as an entirely new additive manufacturing technology. It was introduced in 2016 and since then has achieved phenomenal success. The technology is appreciated by experts across industries and so we must talk about the technology, it’s working, and its applications.

HP’s Multi Jet Fusion Technology is a revolutionary 3D printing technology that additively manufactures strong, functional, and high-performance parts needed for all types of applications.

One of its distinct advantages is the voxel-level control it achieves in printing parts. This control allows the technology to create highly precise and accurate parts.

The MJF technology can be called as a combination of powder bed fusion and binder jetting technologies. It uses a powder material like in the case of powder bed fusion but instead of using costly lasers to fuse the particles, it uses a binding agent to do the job. In addition to the binding agent, the HP Multi Jet Fusion Technology uses another liquid agent called a detailing agent. This detailing agent is sprayed on the areas close to the fusing area to prevent thermal bleeding. The purpose of this detailing agent is to bring out the finest details of the design and also give the printed part a smoother & finer surface. The technology is, therefore, sometimes, referred to as a Multi-agent printing process.

DESIGN GUIDE – HP MULTI JET FUSION

3D Printing

The Multi Jet Fusion printing process starts with the scrapper depositing one layer worth of powder onto the build platform from the powder chamber. Once the powder is evenly spread on the platform, the liquid binding agent is jetted selectively to fuse the particles of the first layer. This is followed by spraying of the detailing agent onto the areas close to the fused areas. The detailing agent prevents thermal bleeding and maintains the surface quality and finish.

The process continues with the movement of the heating lamps over the build platform. This heats the liquid agents and helps in the complete fusing of the layer thus printed. This completes the first layer of printing.

This entire process is then repeated again and again till the entire object is 3D printed in a layer-by-layer form.

Pre-Printing

This is the stage where the 3D CAD model is created and then passed through a slicer software to convert the model into a machine-readable format.

Post-Printing

Once the object is printed, the parts are left in the build chamber where they are allowed to cool down for some time. The object is removed afterwards and is de-powdered with the help of air blasts. And thus the final MJF 3D printed product is obtained.

MATERIALS – HP MULTI JET FUSION

FINISHES – HP MULTI JET FUSION

The Multi Jet Fusion (MJF) technology was initially launched with only a handful of materials, mainly nylon. But since the launch, it has focused on developing new materials through in-house expertise and its material partners like Evonik, Arkema, Henkel, BASF, and others.

We look at some of the materials used on HP Multi Jet Fusion.

Grey surface: as it comes straight out of the 3D printer. Ideal for prototyping and mechanical tests.

Black dyeing finish: a matte black look with consistent colour between batches.

HP 3D High Reusability PA 11: One of the first materials to be made available with the technology. It is ductile and delivers quality parts.

Currently available through Instant Quote

HP 3D High Reusability PA 12: Also one of the materials made available from the launch. It produces strong parts at a low cost.

HP 3D High Reusability PP15: Developed by BASF. It is ideal for functional parts as it exhibits good chemical resistance, has low moisture absorption, and is easily weldable.

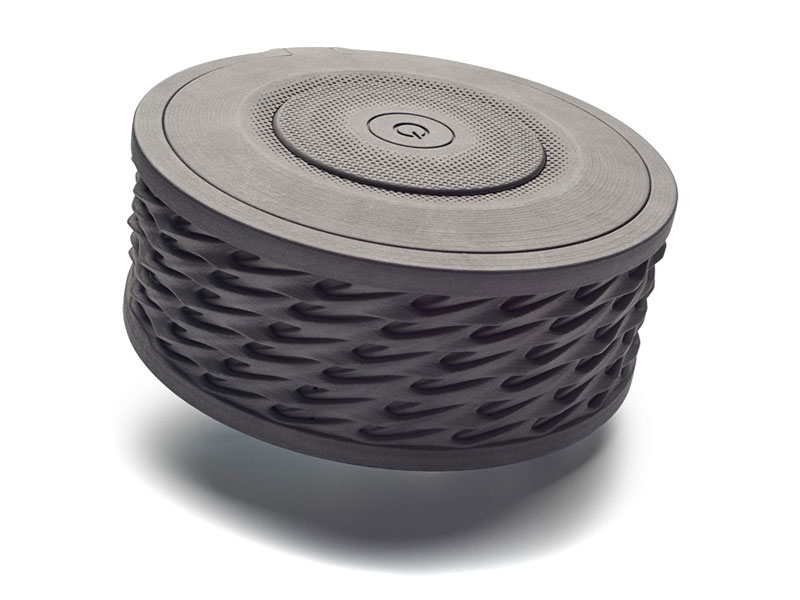

Ultrasint® TPU01: A flexible material developed by BASF

VESTOSINT® 3D Z2773 PA 12: The first-ever certified material for HP Jet Fusion 3D printers9. A multi-purpose affordable thermoplastic material for the production of strong parts, enabling the design of lightweight structures with great colour uniformity.

HP MJF Black dyeing finish

HP MJF Grey finish

Materials used in HP Multi Jet Fusion/Courtesy: HP

TECHNOLOGY – HP MULTI JET FUSION

HP’s Multi Jet Fusion technology finds applications in a wide range of sectors and multiple areas of manufacturing.

Functional Prototyping

MJF is an ideal technology to be used for creating complex functional prototypes. It can easily mimic the utility of the original parts to be manufactured, it delivers dimensionally accurate products, and the parts are tough that can withstand tests like wind tunnel testing.

Rapidly iterating design ideas with HP MJF/Courtesy: Oakley

Kawasaki KX 450 3D Core motorbike/Courtesy: Skorpion Engineering

End-use Products

MJF technology is capable of manufacturing end-use parts for all types of industries and applications. It can be used to manufacture products in aerospace, automotive, sports, footwear, industrial applications, healthcare, prosthetics, etc.

Low-Volume manufacturing

MJF is perfect for low-volume production. The MJF technology uses a powder bed and thus it is possible to manufacture different types of products in a single bed. By carefully arranging the parts to be printed, a significant amount of parts can be produced in one go. This suits low-volume manufacturing.

The classic applications lie in aerospace, vintage cars, spare parts, sports vehicle parts, etc.

Manufacturing Aids

HP MJF parts can be easily customized and are tough and durable. The availability of a range of materials also helps in creating manufacturing aids like jigs & fixtures, maintenance tools, assembly tools, etc., that can withstand heavy loads.

Tooling jigs and fixtures for automotive industry/Courtesy: HP

LookReal dolls were made with HP Multi Jet Fusion technology/Courtesy: HP/YouTube

Customization

HP Multi Jet Fusion technology allows a level of customization never seen before. It worked with a Spanish doll maker, LookReal, to create customized dolls that were unique to each consumer. Through traditional methods, that was difficult to create as all people have different sets of features. But it was made possible by using the HP MJF technology.

Full-Color Applications

HP also delivers full-color 3D printing solutions. It overcomes existing color limitations in 3D printing and helps innovation in product development for both prototyping and production.

Functional and full-color products can be manufactured/Courtesy: HP

Bridge Manufacturing

Bridge manufacturing refers to the concept of using 3D printing technologies to rapidly manufacture products when the production lies between product launch and full-scale manufacturing. This helps in faster time-to-market. The bridge manufacturing continues only until the traditional tooling (dies and molds) is manufactured.

Bridge manufacturing is generally employed to introduce new products in the market at a rapid pace.