Say you potentially have a revolutionary idea in your head and on paper.

How do you physically conceptualize your design?

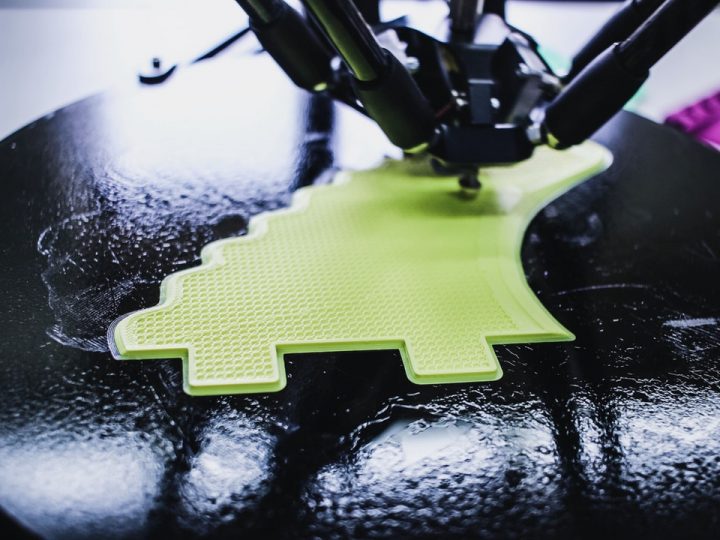

To expand your possibilities, you have to thoroughly test and examine the functionalities surrounding your idea. In other words, you need a 3D-printed model or prototype.

We can assist you with your 3D prototype. We know everything you need to know in regards to 3D prototyping. Rapid prototyping is the largest application for 3D printing because of its significant benefits.

Do you have an interest in learning more about 3D printing and how it benefits you? As you continue reading, we will walk you through the advantages of having a tangible design.

Why a 3D-Printed Prototype?

3D printing is highly adaptable and customizable. It is a cost-effective way to test your initial design before presenting your product. You may create various design iterations efficiently and quickly from the comfort of your own home.

Regardless of whether you need an architectural, engineering, or developmental 3D model, you can print it. Universities, businesses, and companies all utilize 3D printing to meet their project needs. You can print as many as you need with no tooling costs.

Refine your product using 3D printing technology at a reduced cost, starting as low as $3. Feel free to upload CAD files straight into the 3D printer software to reduce time too. The software will read your file and print the products or parts you need immediately.

As a result, 3D printing has always gone hand-in-hand with rapid prototyping production.

Why a 3D-Printed Prototype?

3D printers are remarkable new-age machines that make everyday objects. You can create numerous different projects consisting of different materials, for different purposes. All of this from a single machine you can use at home.

There are even talks about 3D printing human body parts. A revolutionary idea that is possible in the near future because of 3D printing. The endless possibilities are held in your head. You are free to print what comes to your mind and to replace objects that are lost or broken.

The printer makes a 3D model through a process that turns a whole object into thousands of tiny little slices. These derivatives are stacked to make an integral solid form. You can create moving parts such as wheels and hinges, additions to your object. Without the use of tools, you may even print an entire bicycle.

3D Printing and Rapid Prototyping

Rapid prototyping and 3D printing were once considered interchangeable terms. However, rapid prototyping and 3D printing are simply associated in respect to one another.

Rapid prototyping is more accurately a general term for a technique. This general technique defines the rapid process of producing models and prototypes. Producing these models demand casting, molding, and projecting. Out of the many ways you can choose to conduct rapid prototyping, 3D printing is the most common method.

3D printing is the preferred method of rapid prototyping because it eases the engineering process. Each physical prototype needs a fresh design to be made by an outsourced manufacturer. That means long waits and costly investments.

3D printing reduces the cost and speeds up the process. The process is sped by having the option to immediately make your design tangible. You can use different filaments to bring your design to life. You maintain confidentiality for your original ideas as you print from your home or office.

You may even physically conceptualize your design to hold in your hands in less than 30 minutes. Larger designs may take hours, but that is very rapid compared to a manufacturer.

3D Printed

3D printing has evolved to keep up with hardware capabilities as much as possible. Utilizing both CAD software and a 3D printer has taken prototyping to new levels as a result. You now have several options allowing you to use filament comparable to your end-use material.

With a durable filament, you can test how well your design will resist factors such as weather and chemical applications.

Examples of durable filament are listed below:

- Polylactic acid (PLA)- most popular filament

- Acrylonitrile butadiene styrene (ABS)- high-temperature resistance

- Polyethylene terephthalate glycol (PETG)- plastic filament

- Thermoplastic elastomers (TPE)- flexible filament

- Nylon- powder-fusion filament with high flexibility, strength, and durability

- Polycarbonate (PC)- medium flexibility, but very high strength and durability

- Wood- not really wood, typically PLA with wood fibers

PLA is the more recommended filament for everyday usage, however, polyethylene terephthalate glycol (PETG). If you are considering the wood filament, the intention with that is to give your project a woody feel. It is not made of real wood.

Having a wide range of filament options allows you to evolve your initial design. You can print the same design while using a different filament for each print. Which in turn enables you to quickly assess what material is best for your project.

Let Us Bring Your Ideas to Life

You can design and bring any of your ideas to life with 3D printing. Having your projects 3D printed brings ease to the rapid prototyping process in a cost-effective way. Choose from various durable filaments and experiment with your ideas before presenting them.

Print from the comfort of your own home without the need for a manufacturer. Allow yourself to keep your creations confidential prior to release with the added privacy. 3D printing is the future everyone is talking about.

Get a quote with us today, and bring your ideas to life.